Horizontal Machining Center

TH-630/TH-680/TH-800

Carefully built by Tailift, the TH-630 Horizontal Machining Center has been widely recognized by industries in machining efficiency. No matter what structural rigidity or high-speed machining, the TH-630 HMC machine will fully demonstrate its exceptional performance.

Features

- Traveling column.

- Step type linear ways deployment on X-axis.

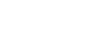

- Rotary type auto pallet change.

- Table indexing 1° (standard), 0.001° (optional).

- Max. cutting capacity Ø1000mm.

- Three axes rapid traverse: 24 M/min. (standard), 30 M/min. (optional).

- Roller type linear ways on three axes.

X, Z-axis are one-piece fabricated with high-quality cast iron so as to ensure the machine rigidity and minimum vibration. It also assists in upgrading machining accuracy.

Automatic pallet change is driven by hydraulic cylinder, and pallet change motions can be performed by 180° rotation clockwise or counter-clockwise.

The X, Y, Z-axis are all mounted with extra wide (SR65) heavy duty linear motion guides together with great span between linear ways, featuring heavy load resisting capability, high feed rate and low friction.

The two linear ways on the X-axis are deployed as a step type and the step difference between linear ways reach 100mm. This design will enable the spindle head to maintain at an extremely stable condition during cutting.

The table is driven by a servo motor in combination with the use of curvic-teeth clutch for high precision indexing.

The pallet positions on 4 precision cones to achieve high positioning accuracy.

Specifications

| Item | Utit | TH-630 | |

|---|---|---|---|

| Travel | X-axis travel | mm | 1050 |

| Y- axis travel | mm | 850 | |

| Z- axis travel | mm | 1000 | |

| Table | Working surface | mm | 630 x 630 |

| No. of tables | pcs | 2 | |

| Table surface type | type | 24-M16Pitch125 | |

| Table indexing unit | degree | 1º (0.001º Optional) | |

| Repeatability | sec. | ± 1” | |

| Table height from floor | mm | 1315 | |

| Max. workpiece size | mm | Ø1000 | |

| Max. table load | kg | 1200 | |

| Max. height of workpiece | mm | 1000 | |

| Spindle | Spindle speed | rpm | 6000 (4500 Optional) |

| Spindle type | Belt (Direct-drive / Gear Optional) | ||

| Spindle nose taper | mm | 7/24 Taper, No.50 | |

| Spindle center to table surface | mm | 100 ~ 950 | |

| Spindle nose to table center | mm | 150 ~ 1150 | |

| Spindle nose taper | BT50 | ||

| Inside dia. of spindle bearing | mm | Ø100 | |

| Feed Rate | Rapid traverse (X, Y, Z-axis) | M/min | 24 (30 Optional) |

| Cutting feed rate | M/min | 1 ~ 10 | |

| Auto Tool Changer | Tool shank type | BT50 | |

| Tool storage capacity | tools | 40 (60/90/120 Optional) | |

| Max. tool diameter | mm | Ø115 | |

| Max. tool dia.(adjacent empty tool) | mm | Ø230 | |

| Max. tool weight | kg | 20 | |

| Max. tool length | mm | 400 | |

| Tool change time(tool to tool) | sec. | 3.2 (60Hz) | |

| Auto Pallet Changer | No. of pallets | piece | 2 |

| Pallet change type | Rotary type | ||

| Pallet change time | sec | 18 | |

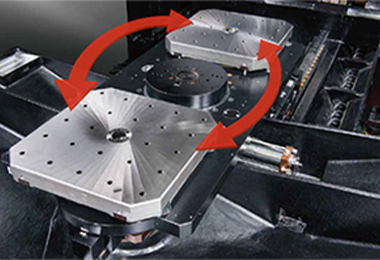

| Machine Dimensions | Machine height | mm | 3540 |

| Area occupied | mm | 4820 x 6820 | |

| Machine weight | kg | 23000 |

Accessories

Standard

- Rotary type automatic pallet changer (APC)

- 1° indexing rotary table

- Link type chip conveyor with chip bucket

- 40 tools chain type magazine

- BT-50, 6000rpm belt-drive spindle

- Spindle oil cooler

- Heat exchanger for electrical cabinet

- Automatic lubrication system

- Fully enclosed splash guard

- Mitsubishi or Fanuc CNC control

- Leveling bolts and blocks

- Tool box

- Operation and maintenance manual

- Spindle air curtain

- Top flushing device

- Chip augers (both sides)

- Coolant jets around spindle

- Simple oil fluid separator

- Three-color warning lamp

- Working light

Optional

- 0.001° indexing rotary table

- 60/90/120 tools chain type magazine

- #50, 4500rmp gear-drive spindle

- #50, 8000~12000rpm direct-drive spindle

- #50, 10000rpm built-in type spindle

- Coolant through spindle device (20 bar)

- Coolant through spindle device (70 bar)

- Linear scales on three axes

- Oil fluid separator

- Air conditioner for electrical cabinet

- Automatic tool measuring device

- Automatic workpiece measuring device

- Transformer

- Oil mist collector

- Rotary table with T-slots

- CE specifications