Features

- All major structural parts are manufactured from Taiwan’s high quality Meehanite cast iron, which are stress relieved for outstanding stability and minimum deformation.

- The double-wall box type base combined with oversized column design lead to higher rigidity and stability.

- Structural parts are manufactured from high quality Meehanite cast iron.

- Double-wall box type base.

- Oversized column structure.

The spindle runs in class P4 precision bearings and is dynamically balanced, which exhibits optimal dynamic accuracy with long lifespan.

The spindle runs in high precision bearings with 100 mm spindle diameter to upgrade the spindle’s rigidity and heavy cutting capability.

The gear-drive spindle head provides two ranges of high low speed change. High torque output in low speed range allows for heavy cutting.

The lubrication system employs a volumetric type oil distributor and bronze oil tubes to resist acid / alkaline and corrosion.

Specifications

| Item | Utit | VMC-147G | VMC-168G | VMC-168B | VMC-188G | VMC-188B | |

|---|---|---|---|---|---|---|---|

| Travel | X-axis travel | mm | 1400 | 1600 | 1800 | ||

| Y- axis travel | mm | 720 | 850 | 850 | |||

| Z- axis travel | mm | 700 | 700 | 700 | |||

| Spindle Nose to Table | mm | 200 ~ 900 | 150 ~ 850 | 150 ~ 850 | |||

| Spindle Center to Column Face | mm | 800 | 930 | 930 | |||

| Table | Working surface | mm | 1500 x 700 | 1800 x 820 | 1900 x 850 | ||

| T-slots (width*number*pitch) | mm | 18 * 5 * 125 | 18 * 5 * 150 | 18 * 5 * 150 | |||

| Max. table load | kg | 1800 | 2500 | 3000 | |||

| Spindle | Spindle speed | rpm | 6000 | 6000 | 6000/10000 | 6000 | 6000/10000 |

| Transmission | Gear | Gear | Belt/Dire. drive | Gear | Belt/Dire. drive | ||

| Spindle nose taper | BT50 (BBT50 Opt.) |

BT50 (BBT50 Opt.) | BT50 (BBT50 Opt.) | ||||

| Feed | Rapid traverse (X,Y,Z-axis) |

M/min | 16 / 16 / 12 | 16 / 16 / 12 | 16 / 16 / 12 | ||

| Cutting feed rate | M/min | 1 ~ 12 | 1 ~ 12 | 1 ~ 12 | |||

| Auto Tool Changer | Tool storage capacity | pcs | 24 (32 Opt.) | 24 (32 Opt.) | 24 (32 Opt.) | ||

| Tool change time (tool to tool) |

sec. | 3.5 | 3.5 | 3.5 | |||

| Max. tool diameter / adj. empty tool |

mm | 110 / 210 | 110 / 210 | 110 / 210 | |||

| Max. tool length | mm | 300 | 300 | 300 | |||

| Max. tool weight | kg | 15 | 15 | 15 | |||

| Miscellaneous | Coolant tank capacity | L | 330 | 330 | 330 | ||

| Electric power required | KVA | 35 | 35 | 35 | |||

| Air pressure required | kg/c㎡ | 6 | 6 | 6 | |||

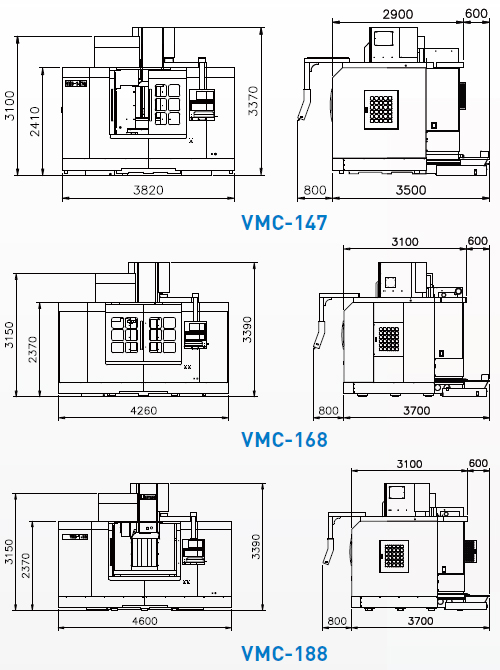

| Machine dimensions (W*L*H) |

mm | 3820x4250x3370 | 4260 x 4420 x 3390 | 4600 x 4420 x 3375 | |||

| Machine weight | kg | 13200 | 16500 | 15500 | 17000 | 16500 | |

Accessories

Standard

- Tools, tools kit

- Working lamp

- Pilot lamp

- Coolant gun

- Chip spray

- Cutting coolant system

- Cutting air blast

- Spindle air blast

- Seat flushing system

- Auto lubrication system

- Auto power off

- RS-232

- Heat exchanger

- Spindle oil cooler

- Arm type ATC 24 tools

- Hinged type chip conveyor

- Leveling adjustment pads and bolt

- Full enclosed splash guard

- Machine, Electricity, operation manual

Optional

- Coolant through spindle device

- Linear scale

- Hydraulic system

- Oil mist collection device

- Rotary working table ( The 4th axis )

- Safety door

- Oil skimmer

- Auto tool length measurement

- Oil hole holder function

- Work piece measurement system

- Transformer

- Full enclosed splash guard